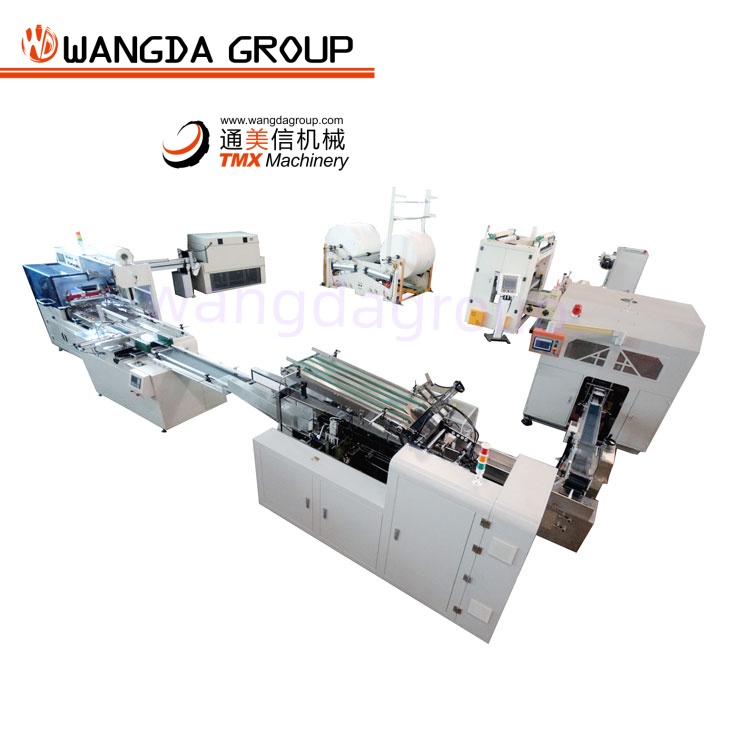

Machine Model | WD-FT-PLI 4-10 |

Jumbo Roll Width | 840mm,1260mm,1470mm, 1680mm, 2100mm( depends on your requests) |

Jumbo roll diameter | 1500mm |

Jumbo roll inner core diameter | ¢76.2mm |

Speed | 90-110 m/min or 10logs/min |

Power | 35 KW,380V,50Hz,3P |

Expand size (mm) | 175mm,180mm,190mm,200mm,210 mm , need specify |

Tissue fold size(mm) | 87.5mm, 90mm, 95mm, 100mm,105mm,need specify |

Tissue height(mm) | 50mm-150mm |

Optional Devices | Full embossing;Lamination device, Edge embossing device |

Machine Model | WD-FT-LSMI |

Cutting length | 90-450mm |

Cutting width | 40-120mm,130-150mm need order |

Cutting height | 60-120mm please point out |

Speed | 80-100cuts/min |

Power | 4KW ,380V,50HZ,3P |

Dimension(L×W×H) | 4100*1040*2100MM |

Weight | 1500KG |

Machine Model | WD-FT-CBSMII |

Maximum packing specification | L(140-240)mm×W(90-110)mm×H(60-110)mm |

Packing speed | 60-80 boxes/minute |

Hot melt machine power | 3.2KW |

Power | 380V 50Hz 3P |

Machine noise | ≤80dB |

Air supply | 0.5-0.8 Mpa |

Air consumption | 120-160L/min |

Outline dimensions | 3100×1400×1500mm |

Machine weight | 1000Kg |

Machine Model | WD-SM-600-A |

Maximum packing specification | Max height:200mm,Max width:600mm, width+height≤600mm |

Packing speed | 40 m/min |

Film type | POF film,PE film |

Power | 11.5KW,380V,50HZ,3P |

Air pressure | 0.5MPa (5 bar) |

Outline dimensions | 2290 x 1025 x 1525 mm, 2530 x930 x 1270 mm |

Machine weight | 2000KG |